So you noticed that your car lacks a bit of power and you check under the hood and find that your spark plugs need to be replaced. You go to the auto shop and get yourself the correct replacement and install them expertly. You take your car for a spin and don’t notice any difference. The problem you might be facing is a gap problem. Regardless of whether the spark plug packaging says that they have been pre-gapped, they could still have been damaged or altered on the way to the shop. This is why you should manually gap your spark plug to ensure proper function.

1. Learn your vehicles gap specifications

Not all cars are made the same and therefore sparkplugs are made to be adjusted. Most cars require a 0.028-0.06 gap between the electrodes. Your car’s manual will be your first and most reliable option, but if you don’t have a manual, you can always consult the auto parts store.

If your engine has been modified for more power, then the gap needs to be smaller as well. The general rule is that the more power of the engine, the smaller the gap between the electrodes.

2. Selecting a gap tool

There are a variety of tools available, but some tools work better than others, depending on the make and model of the spark plug. One feature that most of the tools have is a flat edge to bend the electrode with.

The most common tool is the coin-style gap measure. This tool has an edge that gets thicker as you slide it through the gap. Where the coin stops, is where you will be able to read the width of the gap.

The wire coin gap works pretty much the same, but instead of having a continual gradient on the edge of the coin, you have a number of wires with varying thicknesses.

Then you also get the blade style gap measure that looks like a pocket knife. It has blades of varying width and you slide the blades between the gaps to get a feel for the gaps.

3. Cleaning

If you are installing new spark plugs, then cleaning is not required. However, used sparkplugs build up a whitish residue that could affect the measurement. In this case, you should take a cloth and 90% quick-drying alcohol to remove the residue. If the build-up is too much or that contact points have any black residue on them, they might have outlived their prime and need to be replaced.

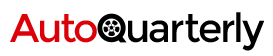

4. Measuring

Once you have cleaned the plug, it is time to measure the gap. Use the measuring tool to establish the gap. If you can pass the tool through the gap without touching both electrodes, then the gap is too wide. If you can’t fit your tool in between the gap, then your gap is too small and needs adjustment.